All you need to know about Power Failure Alert device

Introduction

In today’s fast-paced world, uninterrupted power supply is crucial for businesses and households alike. Imagine having a reliable solution that not only detects power failures but also sends instant SMS alerts to keep you in the loop.

This user-friendly device, renowned for its effectiveness and easy interface, sends SMS alerts on power failure occurrences or restorations, preventing potential disasters. Effortlessly configure multiple user registrations, making it versatile for safeguarding stock in freezers, server systems, healthcare facilities, and computer systems.

The Power Failure SMS Alert Device is a cutting-edge gadget designed to provide real-time notifications when power interruptions occur.

Power failures, or blackouts, can have significant impacts on various aspects of daily life and various industries. Here are some applications or areas where power failure can have notable consequences:

How it Works

The Power Failure SMS Alert Device utilizes advanced sensors to detect changes in electrical currents. Upon sensing a power failure, it triggers the sending of SMS alerts to the designated contacts.

Upon detection, the device utilizes its built-in GSM (Global System for Mobile Communications) module to send SMS alerts to predefined contacts. This ensures that users receive instant notifications on their mobile devices, keeping them informed about the power outage status.

The device’s intelligent system also includes a battery backup feature, allowing it to function seamlessly during power disruptions, guaranteeing continuous monitoring and alerting capabilities.

Applications

- Heating and Cooling:

- Power outages can affect HVAC systems, leading to discomfort, especially in extreme weather conditions.

- Power outages can affect HVAC systems, leading to discomfort, especially in extreme weather conditions.

- Refrigeration:

- Perishable food may spoil if refrigeration is disrupted for an extended period.

- Perishable food may spoil if refrigeration is disrupted for an extended period.

- Manufacturing:

- Power outages can halt production lines, leading to financial losses and disruptions in the supply chain.

- Power outages can halt production lines, leading to financial losses and disruptions in the supply chain.

- Data Centers:

- Uninterruptible power supplies (UPS) are critical for data centers to avoid data loss and maintain service continuity.

- Uninterruptible power supplies (UPS) are critical for data centers to avoid data loss and maintain service continuity.

- Healthcare Facilities:

- Hospitals and clinics rely on continuous power for critical equipment and life-support systems.

- Hospitals and clinics rely on continuous power for critical equipment and life-support systems.

- Retail:

- Point-of-sale systems, lighting, and security systems may be affected.

- Point-of-sale systems, lighting, and security systems may be affected.

- Traffic Lights:

- Power failures can disrupt traffic signals, leading to traffic jams and safety hazards.

- Power failures can disrupt traffic signals, leading to traffic jams and safety hazards.

- Public Transportation:

- Electric trains and buses may be affected, disrupting public transit services.

- Electric trains and buses may be affected, disrupting public transit services.

- Telecommunications:

- Power outages can disrupt phone services, internet connectivity, and other communication systems.

- Power outages can disrupt phone services, internet connectivity, and other communication systems.

- Emergency Services:

- Police, fire, and medical services may face challenges in responding to emergencies.

- Police, fire, and medical services may face challenges in responding to emergencies.

- Banking Systems:

- ATMs, online banking, and other financial services may be temporarily unavailable.

- ATMs, online banking, and other financial services may be temporarily unavailable.

- Stock Exchanges:

- Trading activities can be impacted, affecting financial markets.

- Trading activities can be impacted, affecting financial markets.

- Schools and Universities:

- Power outages can disrupt classes, online learning platforms, and research activities.

- Power outages can disrupt classes, online learning platforms, and research activities.

- Water Treatment Plants:

- Power failures can impact the pumping and treatment of water, affecting the supply of clean water.

- Power failures can impact the pumping and treatment of water, affecting the supply of clean water.

- Sewage Systems:

- Treatment and disposal of sewage may be affected, leading to potential environmental and health issues.

- Treatment and disposal of sewage may be affected, leading to potential environmental and health issues.

- Irrigation Systems:

- Automated irrigation systems may fail, affecting crop health.

- Automated irrigation systems may fail, affecting crop health.

- Livestock:

- Power outages can impact heating and cooling systems for livestock, especially in extreme weather conditions.

- Power outages can impact heating and cooling systems for livestock, especially in extreme weather conditions.

- Entertainment and Recreation:

- Power failures can disrupt entertainment events and recreational activities in cinemas, theme parks, and sports venues.

- Power failures can disrupt entertainment events and recreational activities in cinemas, theme parks, and sports venues.

- Public Services:

- Government offices may face disruptions in providing services to the public.

- Government offices may face disruptions in providing services to the public.

Advantages

For businesses heavily reliant on electronic systems, a power failure alert system is indispensable for maintaining seamless operations. It enables secure system shutdowns or swift activation of backup power, preventing data loss and service interruptions.

Individuals with medical conditions relying on powered medical equipment benefit from power failure alerts. It allows them to switch to backup power sources or take necessary measures to ensure the continuous functioning of critical medical devices.

Strategic use of power failure alert devices not only prevents equipment damage but also minimizes downtime and optimizes backup power efficiency.

Conclusion

power failures, or blackouts, have far-reaching implications across various sectors, affecting both daily life and industries. The consequences range from discomfort in heating and cooling systems to disruptions in critical services like healthcare, transportation, and emergency response. Industries such as manufacturing, retail, and finance face financial losses and operational setbacks during power outages. Educational institutions, water treatment plants, and agriculture also grapple with challenges, impacting learning, water supply, and crop health.

The vulnerability of interconnected systems becomes apparent as power failures can trigger a domino effect, disrupting not only utilities but also communication channels, transportation networks, and essential services. While backup systems such as uninterruptible power supplies (UPS) provide some resilience, the widespread impact of blackouts underscores the need for comprehensive strategies to ensure energy reliability.

As we navigate the complexities of a modern, technology-driven society, addressing the consequences of power failures requires collaborative efforts from industries, governments, and individuals. Embracing sustainable energy solutions, implementing robust backup systems, and fostering innovation in energy management are crucial steps toward building a more resilient and reliable infrastructure. By understanding and mitigating the impacts of power failures, we can work towards creating a more secure and sustainable future for all.

Are you intrigued by electromagnetic/magnetic flowmeters (EMF) and their applications?

Are you intrigued by electromagnetic/magnetic flowmeters (EMF) and their applications?  You’re about to have a mind-blowing experience. To see an amazing 3D rendering of an electromagnetic flowmeter, click the link above.

You’re about to have a mind-blowing experience. To see an amazing 3D rendering of an electromagnetic flowmeter, click the link above.

Particularly in sectors where accuracy is crucial, these instruments are a dominant force in fluid monitoring. They have significantly changed the industry thanks to their remarkable precision, dependability, and low maintenance requirements. Join us as we explore their parts, operating principles, benefits, setup, upkeep, precision, uses, calibration, and advice on selection. Buckle up for an educational voyage into the intriguing world of flowmeters!

Particularly in sectors where accuracy is crucial, these instruments are a dominant force in fluid monitoring. They have significantly changed the industry thanks to their remarkable precision, dependability, and low maintenance requirements. Join us as we explore their parts, operating principles, benefits, setup, upkeep, precision, uses, calibration, and advice on selection. Buckle up for an educational voyage into the intriguing world of flowmeters!  ). That is the potency of electromagnetic/magnetic flowmeters!

). That is the potency of electromagnetic/magnetic flowmeters!  They are the preferred choice for a variety of industries thanks to their cutting-edge technology and durable construction.

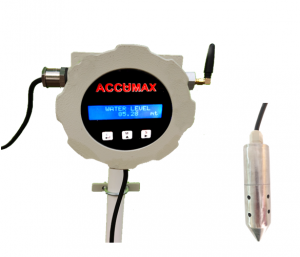

They are the preferred choice for a variety of industries thanks to their cutting-edge technology and durable construction.  Signal Converter: Enhances and modulates the weak electrical impulses from the electrodes to quantifiable outputs.

Signal Converter: Enhances and modulates the weak electrical impulses from the electrodes to quantifiable outputs. Transmitter/Display Unit: With added capabilities like data recording and communication interfaces, the unit grabs the modified pulses and outputs vital data, especially flow rate.

Transmitter/Display Unit: With added capabilities like data recording and communication interfaces, the unit grabs the modified pulses and outputs vital data, especially flow rate.

how these flowmeters operate at this point. Enter its enticing operational/working concept now.

how these flowmeters operate at this point. Enter its enticing operational/working concept now.

Calculation of Flow Rate: Using the observed voltage, the meter determines the liquid’s flow rate by taking electromagnetism and fluid dynamics into account.

Calculation of Flow Rate: Using the observed voltage, the meter determines the liquid’s flow rate by taking electromagnetism and fluid dynamics into account. and welcome to continuous operations! Additionally, even in turbulent fluids and low flow rates, their accuracy levels are exceptional, ensuring precise readings in even the most demanding situations.

and welcome to continuous operations! Additionally, even in turbulent fluids and low flow rates, their accuracy levels are exceptional, ensuring precise readings in even the most demanding situations.  Additionally, they work well with a variety of conducting liquids, including ones with corrosive characteristics or high solid contents.

Additionally, they work well with a variety of conducting liquids, including ones with corrosive characteristics or high solid contents.  ,

, Food and beverage production,

Food and beverage production, , and

, and Pharmaceutical production.

Pharmaceutical production.

Chemical processing

Chemical processing : During bottling and canning, flowmeters give accurate liquid flow measurements, ensuring product quality, uniformity, and flavor perfection in every container.

: During bottling and canning, flowmeters give accurate liquid flow measurements, ensuring product quality, uniformity, and flavor perfection in every container.

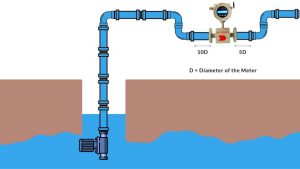

Pre-Installation Checklist:

Pre-Installation Checklist: Installation Process:

Installation Process: Calibration and Re-Calibration:

Calibration and Re-Calibration: Your electromagnetic/magnetic flowmeter will operate accurately and dependably if it is installed, maintained regularly, and calibrated on schedule.

Your electromagnetic/magnetic flowmeter will operate accurately and dependably if it is installed, maintained regularly, and calibrated on schedule. Pipe size: Verify conformance with the conduit size.

Pipe size: Verify conformance with the conduit size. Accuracy needs: Determine the required accuracy level.

Accuracy needs: Determine the required accuracy level. Installation: Consider how simple it is to install.

Installation: Consider how simple it is to install. Maintenance costs: Costs associated with maintenance should be factored in.

Maintenance costs: Costs associated with maintenance should be factored in. queries or remarks you may have regarding electromagnetic/magnetic flowmeters in the comments section.

queries or remarks you may have regarding electromagnetic/magnetic flowmeters in the comments section.  We’re excited to hear from you and here to assist!

We’re excited to hear from you and here to assist!