Flow meters with Latest CGWA Guidelines

According to the notice issued by the Authority on 08.01.2021, all the industries extracting water from ground, except exempted categories, should install flow meters meeting CGWA guidelines having Telemetry system, or they will be liable for penalty. The industries should install the meters and confirm it with the CGWA about installation within 30 days from the date of NOC issued to them.

The flow meters shall meet below specifications as per the guidelines:

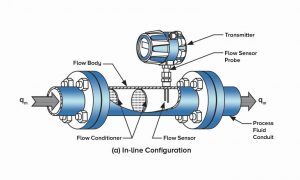

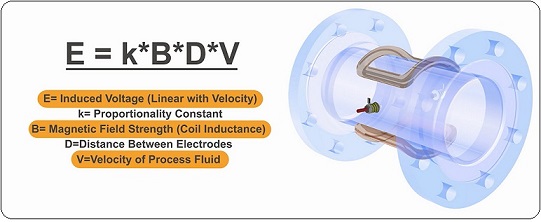

The flow meter shall be either Electromagnetic flow meter of Ultrasonic meter.

The meter shall be either battery operated or power should be supplied through UPS.

The meter shall be as per ISO 4064:2014 Standards having flow range accuracy better than +2.

The meter and telemetry system should be sealed in a way that any attempt to open the system breaks the tag.

The manufacturer shall submit latest NABL / FCRI / NPL certificate for every meter.

The telemetry system shall record the flow data directly to the cloud server that is further empaneled with The Ministry of Electronics and Information Technology.

The meter shall transmit following parameters to the server

- Timestamp

- Cumulative Forward Flow

- Cumulative Backward Flow

- Cumulative Net Flow

- Cumulative Pump working Hours

- Meter serial number

- Borewell id (as per CGWA)

- Device last calibration date

Accumax flow meters meet specifications as per CGWA Guidelines: